HB-2 Anti-Corrosion Rubber Lining

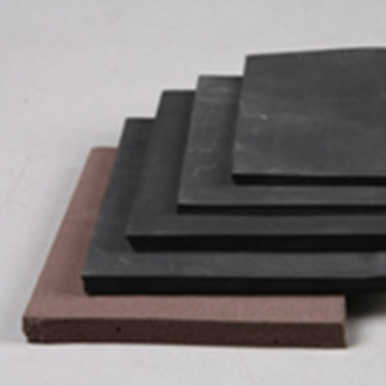

Structure:

Application: The rubber sheet is used in equipment with strong acid, alkali and negative pressure, high temperature, and other environmental requirements. It is suitable for protecting steel equipment or pipelines from being corroded.

product description

Materials

Heat vulcanized natural rubber lining, vulcanized at the construction site

The rubber sheet consists of rubber, reinforcing filler, vulcanizing materials, antioxidant, softening plasticizer, and other relevant materials.

Physical Property:

| Test Items | Index | Actual Index | Standard | ||||

| Hardness Shore D | 70-85 | 78 | GB/T 531 | ||||

| Tensile strength MPa≥ | 10 | 16 | GB/T 1701 | ||||

| Transverse tensile strength MPa≥ | 65 | 70 | GB/T 1696 | ||||

| Impact strength J/m3≥ | 200×103 | 245×103 | GB/T 1697 | ||||

| Adhesive strength MPa≥ | 9 | 11 | GB/T 11211 | ||||

| Condition for anti-medium test | 85℃×7d | ||||||

| 40%H2SO4 △W% | -3 to +5 | 0 | GB/T 1690 | ||||

| 20%HCl △W% | -3 to +10 | 1 | GB/T 1690 | ||||

| 70%H3PO4 △W% | -3 to +5 | 0 | GB/T 1690 | ||||

| 40%NaOH △W% | -3to +5 | 0 | GB/T 1690 | ||||

Medium

General environment: weak acid or alkali, salt solution, sea water

Harsh environment: hydrochloric acid, sulfuric acid, sodium hydroxide

In addition, the rubber sheet is suitable for equipment and environment where negative pressure and high temperature are required.

Working Temperature: -20℃ to +130℃

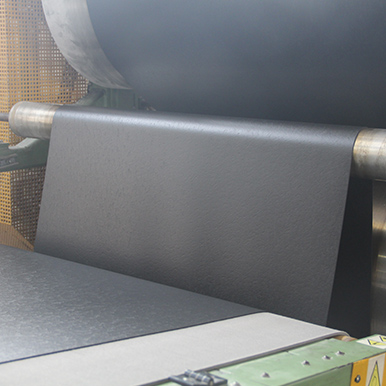

Vulcanizing Method: Being vulcanized and lined at the construction site

Application

The rubber sheet is used in equipment with strong acid, alkali and negative pressure, high temperature, and other environmental requirements. It is suitable for protecting steel equipment or pipelines from being corroded.

Tyre Company

Tyre Company